Clothing Tech Pack Designer | Garment Manufacturer

Clothing Tech Pack Designer and Clothing Manufacturer Offering End to End Service to Fashion Brand starting from Fashion Design, Tech Pack Design, Sampling and Garment Manufacturing.

Apr 24, 2024

How to Leverage Your Tech Pack to Streamline Production and Sourcing Decisions

Dec 6, 2023

13 Essential Tricks to Build and Grow Your Clothing Brand

As a fashion tech pack services for designers and brands, we maintain strong connections with the brands we collaborate with. We actively exchange experiences, providing valuable technical and market insights to foster the growth of our clients. In this blog post, we aim to share some valuable experiences our clients have graciously shared with us throughout our partnership. This post caters explicitly to individuals aspiring to launch their apparel brand, serving as a useful resource for starting and effectively managing such a venture.

1. Strategic Launch: Maximizing Profits with a Modest Batch and Quality Control Measures

If operating on a limited budget,

consider starting with just one t-shirt featuring a compelling print. Instead

of a large quantity, begin with a modest batch of 100 pieces in two color options. This initial investment will be $1000 TO $1500, translating to a cost of $10 per tee, which is quite affordable. You can ensure a reasonable profit margin by pricing each t-shirt between $25 to $30 per piece. This is a standard calculation employed in various business

ventures. Maintaining a smaller stock can minimize delivery times and

enhance quality control measures.

2. Captivating Visuals: Exploring Cost-Effective Alternatives for Product Showcase Photography

To effectively showcase your

products, conducting a photo shoot with models can be a highly beneficial

approach, mainly when selling through e-commerce platforms. However, it

is not an obligatory requirement to use models. Numerous successful brands choose not to utilize models and still achieve impressive sales. A product-focused photo shoot can be a cost-effective alternative if you are operating on a tight budget. By doing so, you can save a significant

amount of money that can be allocated towards building up your inventory.

3. Targeted Social Media Strategy: Leveraging Platform Intentions for Effective Brand Engagement

While numerous social media platforms are available, few are genuinely effective. It is

crucial to comprehend the intentions of individuals when they visit these

platforms. For instance, when someone visits Facebook, their primary goal is

often to pass the time rather than actively seeking products or information.

Conversely, if someone trips Reedit, they are likely searching for answers or

sourcing specific information. Choosing the social media platform that aligns best with your product and target audience is essential. Even if you

receive a relatively low number of views, converting even one viewer into a customer can be considered a positive outcome. Quality over quantity

remains critical in such scenarios.

4. Product Excellence: Prioritizing Quality and Craftsmanship for Lasting Brand Impressions

When launching your brand, it is crucial to

prioritize your end products over branding and packaging. While impressive

branding and packaging May initially capture attention, they are often discarded shortly after. Instead, focus on creating exceptional products like

t-shirts or hoodies that leave a lasting impression on your customers. By

providing high-quality items, customers will be reminded of your brand each time they wear them. Therefore, invest in superior product quality and let

your customers become ambassadors who speak highly of your brand. To achieve

this, it is crucial to have well-crafted designs and accurate tech packs for

production. Opt for custom design and production processes to ensure

uniqueness. Additionally, having a skilled tech pack designer to offer guidance is always advantageous.

5. The Power of Collaboration: Leveraging Business Partnerships for Enhanced Productivity and Success

Starting a business requires more effort than

one person can handle alone. That's why having a reliable business partner or a

helping hand is invaluable, particularly if they possess insights into the

garment development life cycle. Collaborating with a business partner is an intelligent decision as it allows you to leverage each other's strengths and

compensate for weaknesses. By dividing responsibilities, you can

efficiently manage various aspects of the business. For instance, if you excel

in marketing, your partner can focus on design and operations, creating a well-rounded

team. The comfort level with this arrangement depends on your personality

and working style, but having a partner to share the workload can significantly

enhance productivity and outcomes.

6. Harnessing the Power of Feedback: Improving Design Success through Collaboration and Insight

Creative design is inherently unpredictable. Determining how well a design will resonate with your audience is difficult.

Sometimes, designs you anticipate succeeding may fall short, while others

you underestimate can perform exceptionally well. However, customers will still be drawn to your products if they have impeccable fit and quality. To

increase the chances of a successful design, seeking the opinions of others can

be beneficial. Consult a small group of trusted friends or consider

posting on Reddit to gather feedback. It's essential not to take

feedback personally and understand that you seek input to improve your brand. Critical or seemingly offensive feedback can provide valuable insights and contribute to your growth.

7. Rising Above the Crowd: Prioritizing Quality and Design Excellence in the Streetwear Market

The streetwear market is saturated with

numerous brands, and everyone in the USA wants to start their own

streetwear brand. However, it's important to note that only a tiny percentage

of these brands prioritize quality. Many startup brands neglect proper product

development, resulting in subpar design aesthetics and frequent fit complaints.

They are hesitant to invest in design and fits yet expect exceptional results.

Consequently, they often fall short of achieving success. Despite the market

saturation, building a successful and profitable streetwear brand is still possible. It's essential not to get discouraged by the competition and

challenges. By prioritizing quality, investing in design excellence, and delivering exceptional fits, you can create a brand thriving in this competitive industry.

8. Logo T-Shirts: Enhancing Marketability with Eye-Catching Designs

As a small brand, logo t-shirts tend to

resonate well with customers. The size and attractiveness of the logo play a

crucial role. Customers are drawn to logos with appealing colors that look

visually pleasing, increasing the likelihood of making a sale. If you're a new

brand planning to sell logo t-shirts, choosing high-quality blanks in attractive colors that complement your logo is essential. However, if you launch with

text-only logo items, it may be challenging to generate significant sales as

they may need to capture the same level of attention. Therefore, it is advisable to

prioritize incorporating a visually appealing logo into your merchandise to

enhance its marketability.

9. Quality over Quantity: Choosing Authentic Influencers for Effective Brand Collaborations

Influencers can indeed play a significant role

in brand promotion, but it is crucial to collaborate with the right

influencers. Having a large follower count does not guarantee effectiveness.

For instance, individuals with 50,000 followers may receive minimal engagement,

such as only 50 likes on their posts, indicating a lack of interest from their

audience. In contrast, an influencer with 10,000 followers who consistently

receives over 500 comments per post demonstrates a higher level of engagement.

This suggests that people take the posts of such influencers more seriously.

When evaluating potential influencers, examining the quality of their engagement is essential. Note who likes and comments on their posts and

assess whether these accounts are legitimate. Fake followers and likes can

devalue your brand, as people can often distinguish between genuine and

artificial engagement. Therefore, it is crucial to partner with influencers with an authentic and engaged audience to maximize the impact of your brand

collaborations.

10. Creating a Thriving Brand Community: Cultivating Local Connections and Engagement

Building your brand's presence and community

should commence well before you start designing your products. Establishing a supportive network of people who will back you from the moment you begin selling is essential. To achieve this, focus on creating a local community or

group. Relying solely on digital marketing or website sales may limit your

reach, as people are more likely to visit your website if they are familiar

with you or have a connection to your brand. Building a local buzz can be

accomplished through one-on-one public relations efforts, such as engaging in

personal interactions and conversations. Additionally, consider implementing

guerrilla marketing campaigns and collaborating with local influencers to

generate more visibility. Participating in local street markets can also be

beneficial, especially for clothing items like t-shirts and pullovers. Starting

a blog where you can gather customer feedback and share recommendations can effectively build engagement and rapport with your

audience. By leveraging these strategies, you can build a

strong brand community and benefit from valuable customer feedback and

recommendations.

11. Forging Lucrative Partnerships: Securing Rack Space in Local Stores

A traditional yet practical marketing approach

that remains relevant is connecting with local stores and securing rack space

for your products. This involves contacting these stores and convincing

them to carry your merchandise. Typically, this arrangement entails sharing your profits with the store as compensation. In the initial

stages, you may need to offer your collection on a consignment basis, meaning

the store only pays for the products once they are sold. Negotiating with local

stores successfully relies on your marketing skills and ability to showcase the

value and appeal of your brand. By effectively conveying the uniqueness and

marketability of your products, you can establish mutually beneficial

partnerships with local stores, expanding your reach and gaining exposure within

your target market.

12. Building an Authentic Brand-cause Partnership for Sustainable Impact

Attaching your brand to a cause, even if it

involves donating a small percentage of your profits, can significantly boost

your sales. This practice creates an emotional connection with customers who

care about positively impacting the world. However, it is crucial to

genuinely align yourself with a cause because you believe in it rather than

solely for brand marketing purposes. Authenticity is critical in building trust and

loyalty with your customers. By genuinely getting involved with a cause, you contribute to a meaningful network and provide an opportunity for

your brand to gain visibility and recognition. Conversely, if your connection

to a cause is purely driven by marketing motives, it can negatively affect your brand's reputation. It's essential to prioritize

sincerity and a genuine desire to make a difference, as this will resonate with

customers and establish a positive brand image.

13. Breaking Down Your Goals and Navigating the Design Process

Feb 18, 2023

Steps in Tech Pack Design Followed in Garment Industry

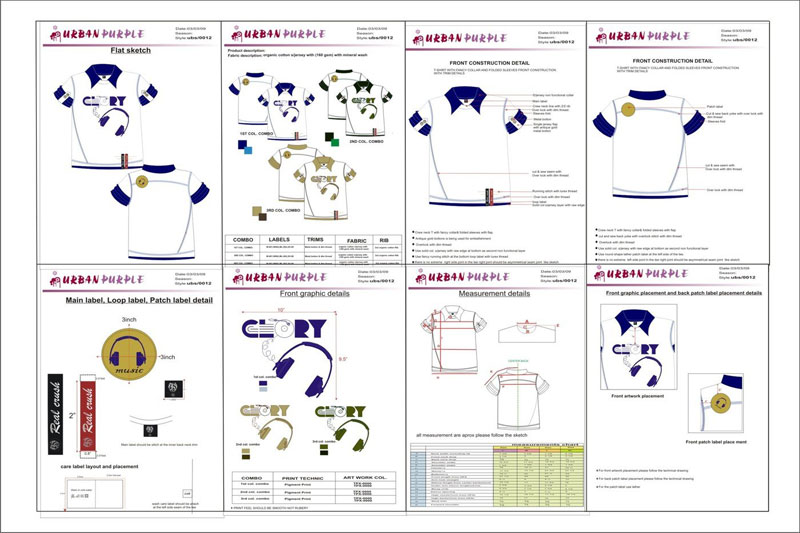

At its core, a tech pack clearly communicates a particular garment's design and style requirements. It provides instructions for the clothing manufacturer to follow throughout production, including everything from pattern design to finishing. Because each process step is essential and requires proper instruction, the tech pack designer must clarify their instructions, directly affecting sample development and production. Each tech pack is unique and tailored to the garment's style and design requirements. In the following points, we'll outline how to create a tech pack and spec sheet for garments to ensure that all critical details are included.

1. Fashion Flats: A Fashion Flat, also known as a Flat Sketch, is a front and back view of a garment that showcases every detail. It is the foundation for the tech pack design, so the designer must include all necessary information. The designer and the client should cross-check the Fashion Flat throughout the design process to ensure that all details are accurately represented.

2. Color Options and Pantone Code: Garment styles are incomplete without color options. Clients often request color variations for each style they design, allowing the brand to offer variety to its customers. Therefore, the tech pack designer should provide 2-3 color options for each style to ensure that the final product meets the client's expectations and offers flexibility for the brand.

3. Fabric Details: Fabric details are critical to any garment tech pack. This information includes the fabric's yarn count, weight, GSM, and composition and is essential for the garment manufacturer to estimate fabric consumption during production. The fabric details also determine the optimal quantity required at a particular price rate, which can impact the overall cost of production. Therefore, the tech pack designer should ensure that all fabric details are accurately included in the tech pack to avoid any issues during the production process.

4. Stitching and Construction Details: Stitching and construction details in a tech pack guide how a clothing manufacturer should stitch and construct the garment. The details show the step-by-step process of assembling the garment, and a tech pack designer with factory experience can provide the necessary expertise to ensure that these details are accurately conveyed. Therefore, including stitching and construction details in the tech pack is crucial to ensure the garment is produced correctly and meets the client's expectations.

5. Graphic and Print Details: Graphics and prints are essential to garment embellishment, and any garment style is complete with them. When incorporating prints and graphics, the placement and technique of the design are crucial to achieving the desired look. The tech pack designer must provide clear instructions for the print's color, size, and placement in the garment. Therefore, including these details in the tech pack is critical to ensure that the final product accurately represents the client's vision. A separate post will be dedicated to further discussing print and graphic details.

6. Graphic/Print Placement Details: Print design is a crucial aspect of tech pack design, but more is needed to create a design. Decisions on the placement of the print, such as whether it will be printed on a garment or a panel, are essential and should be made with the guidance of a technical designer. It's important to remember that even a good print can look like a disaster if placed in the wrong location on the garment. Therefore, the tech pack should include detailed measurements and the exact position of the print from a specific point to ensure that it's accurately executed during production.

7. Embroidery Details: Embroidery has become a popular trend in high-end fashion, and any garment style that features an embroidery design requires detailed instructions. The tech pack should include information on the type of embroidery, the number of stitches needed, the color of the thread, and other relevant details. The number of stitches required for a particular embroidery design is a crucial factor to consider. There are several embroidery techniques, such as puff embroidery, stiffly, and plain lock stitch, and the tech pack designer needs to specify the type of embroidery to be used in the design. Including these details in the tech pack ensures the embroidery is executed correctly during production.

8. Trims Detail: In addition to fabric, garments require other materials such as trims, including buttons, zippers, clip hooks, and more. Each garment style requires different trims, so providing complete details for sourcing and usage is essential. The technical designer must mention the trim details and specifications in the tech pack. For example, the tech pack should specify the button size for a shirt, and the zipper length should be mentioned for the bottom. Including these details in the design is crucial to ensure that the garment is constructed accurately and the style is executed as intended.

9. Branding Details: Every style a technical designer creates is typically for a brand, which should reflect specific branding details. Labels, hang tags, loop labels, and size labels are all part of a brand's identity. While these details may not be part of the tech pack design, it is essential to specify where to attach or stitch them in the tech pack. The most crucial branding trim is the care label, which provides instructions on handling the garment. Including these branding details in the tech pack ensures that the final product aligns with the brand's identity and guidelines.

11. Measurement Details and Size Chart: The measurement spec sheet includes all the critical measurements of the garment, such as the chest, waist, hip, sleeve length, and inseam, along with the tolerance range for each measurement. The size chart and grading rules are also essential to ensure the garment fits appropriately across all sizes. The tech pack designer must work closely with the pattern maker to ensure that the spec sheet is accurate and that the size chart and grading rules are appropriate for the target market.

12. Measurement Guideline: The measurement guideline is an essential part of the measurement spec sheet, as it provides clear instructions on how to take the measurements. It typically includes illustrations and descriptions of where to start and end the measurements and how to position the measuring tape. This helps to ensure that the measurements are consistent and accurate, which is crucial for achieving the desired fit of the garment.

13. Bills of Materials ( BOM ): A Bill of Materials (BOM) is a crucial document in the production process, as it lists all the materials and components required to make a garment. A Bill of Materials is an essential source of information used for production cost estimation. This includes the fabric, trims, hardware, labels, thread, and packaging materials. The production team uses the BOM to estimate the garment's cost and ensure that all the necessary materials are ordered and on hand before production begins. It is also used to keep track of inventory levels and provide sufficient critical components. Preparing an accurate BOM is an essential part of the tech pack design process and requires careful attention to detail and thorough knowledge of the garment's construction and materials.

Urban Purple offers comprehensive services for fashion brands, including design, sampling, production, and shipping. This can be valuable for brands looking for an end-to-end supply chain solution. Additionally, the Tech Pack Template Store can be a helpful resource for brands needing design spec sheet templates. Having a one-stop shop for all these services and resources can be a time-saving and cost-effective option for fashion brands.

The Importance of Fabric Details in Fashion Tech Pack Design

The Importance of Fabric Details in Apparel Tech Packs

Essential Aspects of Fabric Description in Apparel Tech Packs

- GSM testing is essential for fabric evaluation, particularly for knitwear fabrics. GSM, or Grams Per Square Meter, reflects the weight and thickness of the fabric. To calculate the GSM of a fabric, a circular piece is cut to an even size of 11.2 cm and weighed. The weight of the fabric is then used to determine the GSM. This measurement is vital in determining the appropriate use of fabric in a particular garment and ensuring consistency across multiple batches of fabric.

- Yarn Count is an essential aspect of fabric testing, and it refers to the thickness of the yarn used in the fabric. It is calculated by its mass per unit length, and its unit of measurement is "tex." Yarn manufactured by the compact spinning system is known for its better smoothness, higher luster, and improved abrasion resistance compared to classical yarn. It has 40-50% better abrasion resistance, 20-30% lower hairiness as measured with the Uster apparatus, 60% lower hairiness as measured with the Zweigle apparatus, 8-15% higher tenacity and elongation at break, and more minor mass irregularity. Understanding yarn count is crucial in determining the quality and characteristics of the fabric and can help in selecting the appropriate yarn for a particular garment style.

- Fabric Composition: Fabric composition refers to the materials used to create the fabric, which can include a single type of fiber, such as 100% cotton or 100% polyester, or a blend of different fibers, such as a cotton/polyester blend. The composition of the fabric can affect its properties, such as its durability, texture, and breathability, and it is essential to specify the composition in the tech pack to ensure that the correct materials are used in production.

- Color: Pantone is a color-matching system used in the fashion and design industry to ensure consistency and accuracy of colors across different materials, products, and processes. Designers and manufacturers use Pantone colors to specify and communicate the exact shade of a color they want to use in their designs. Pantone provides a wide range of color shades and swatches, and their color codes are recognized globally as a standard for color communication. Using Pantone colors in your tech pack ensures that your fabric and garment colors are consistent and accurate throughout the production process.

Tech Pack Design - Fashion Studio Urban Purple

Benefits of an Integrated Clothing Design Studio and Manufacturer

The Importance of Tech Pack Designs in Garment Manufacturing

Preparing for Tech Pack Design and Clothing Manufacturing

- · Your ideas and sketches/inspiration images

- · Your Brand Logo

- · Base Measurement of any of your competitors or Brands that best fits your segment.